Introduction

Have you ever wondered how large electrical systems manage power distribution so efficiently? The answer often lies in busbar systems—an essential component in modern electrical setups.

In this article, you’ll discover how busbar systems simplify wiring, increase efficiency, and improve performance in industries like manufacturing, renewable energy, and commercial buildings. We will guide you through the key components, types, and considerations for selecting the right busbar system for your needs.

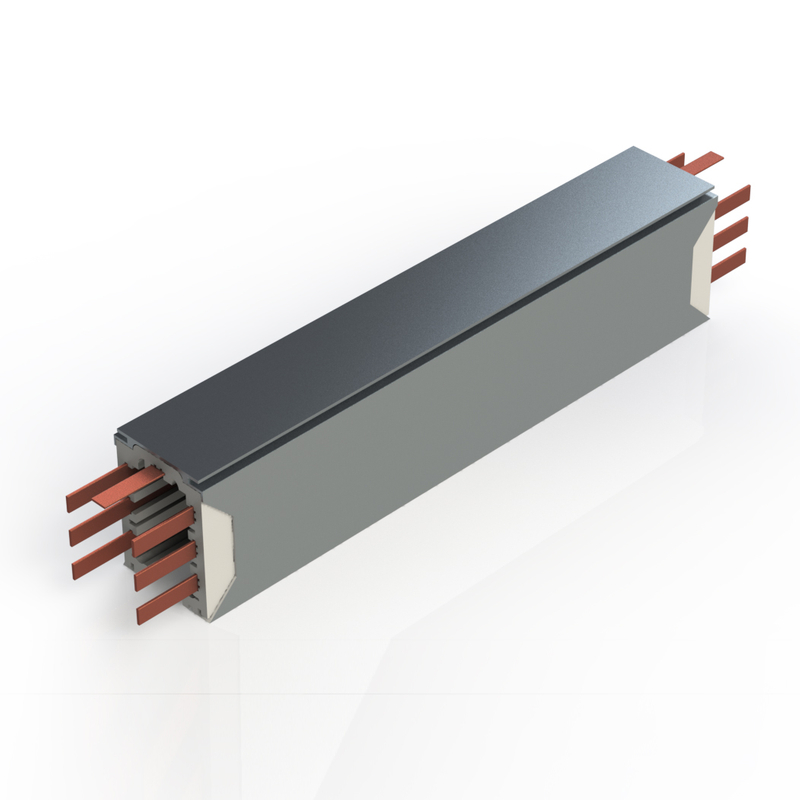

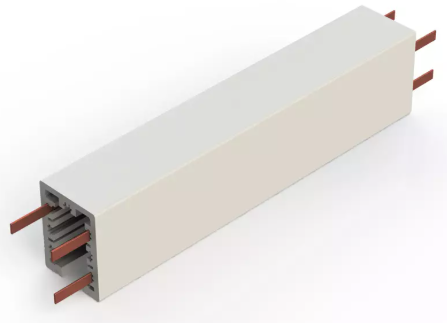

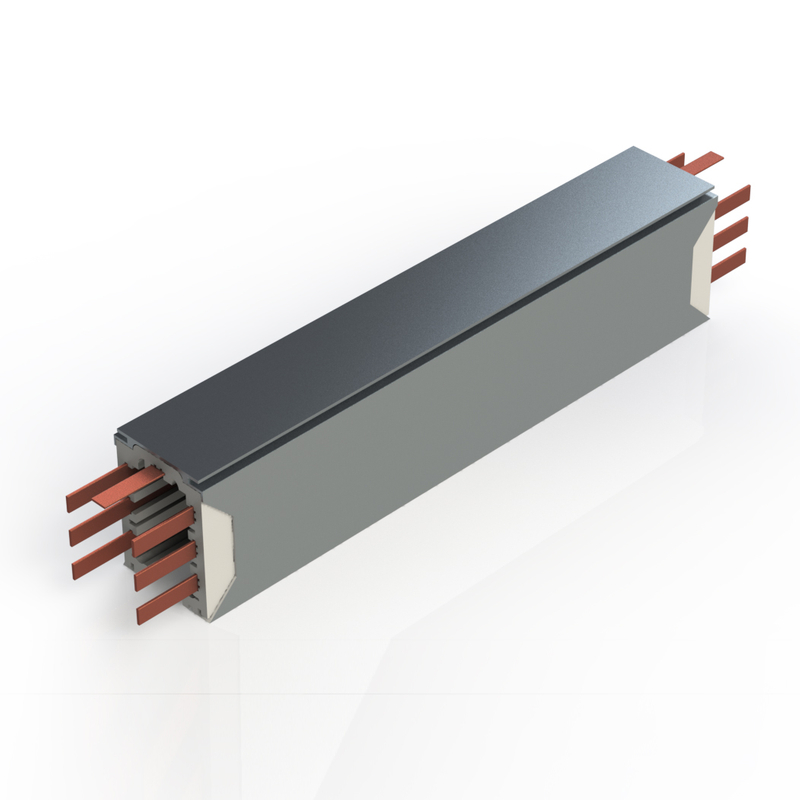

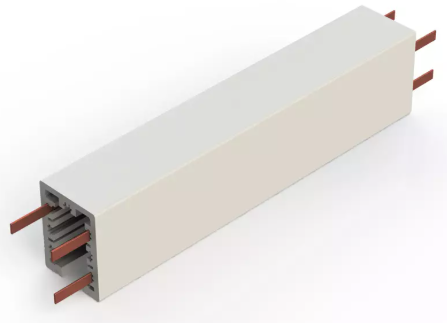

What Are Busbar Systems?

Definition and Functionality

Busbar systems are conductive materials (often copper or aluminum) used to distribute electrical power within a system. They serve as the main hub for connecting multiple circuits, offering a central point for power distribution. Unlike traditional wiring, which can become bulky and disorganized, busbars streamline connections and ensure efficient power flow, especially in high-current environments.

Busbar systems are commonly used in industrial, commercial, and utility power setups, allowing electricity to be distributed across large networks of equipment.

Components of a Busbar System

A busbar system consists of several key components:

● Conductors: Made from copper, aluminum, or other conductive materials, they carry electrical current.

● Insulators: Ensure that the busbar is electrically isolated and prevents short circuits.

● Mounting Hardware: Supports the busbar, ensuring it is securely positioned within the system.

These components work together to ensure safe, reliable, and efficient electricity distribution.

How Busbars Improve Efficiency

Compared to traditional wiring, busbars reduce the need for extensive cable networks. This improves both space efficiency and overall system performance. Busbars can handle high currents without significant heat buildup or voltage drop, ensuring a stable and safe power distribution system.

Types of Busbar Systems

By Material

● Copper Busbars: Known for excellent conductivity, copper busbars are ideal for high-performance applications. They offer low resistance and minimal energy loss but come at a higher cost.

● Aluminum Busbars: Lighter and more cost-effective, aluminum busbars are often used for large-scale applications where weight and budget constraints are important, although they have slightly lower conductivity than copper.

By Shape

● Flat Busbars: These are the most common type, offering a large surface area for heat dissipation. They are often used in industrial machinery and switchgear.

● Round Busbars: Round busbars are flexible and can handle higher current loads. They are typically used where flexibility and higher current-carrying capacity are needed.

● Flexible Busbars: Made from laminated strips, these busbars can be used in confined or irregular spaces, providing an adaptable solution.

By Configuration

● Main Busbar: The primary busbar used for connecting all major components in a system.

● Ring Busbar: A configuration where the busbar is designed in a loop for redundancy and reliability.

● Sectionalized Busbar: A busbar system divided into sections, which can be individually isolated for maintenance.

How Busbar Systems Work

Current Distribution

Busbar systems serve as the backbone for electrical power distribution in various systems. They allow electrical current to flow efficiently and evenly across multiple circuits from a single central point. Busbars are designed to handle high currents, distributing them across various devices with minimal energy loss.

In large-scale power systems, busbar systems connect different parts of the system, such as transformers, switchgear, and circuit breakers, ensuring that electricity is evenly delivered to each component. The current flows through the busbar with minimal resistance, which is critical for maintaining system efficiency.

Power Flow Optimization

One of the key advantages of busbar systems is their ability to optimize power flow. Traditional wiring systems can experience energy loss due to resistance, especially over long distances. However, busbar systems reduce this issue by using materials with high conductivity, like copper or aluminum, to ensure that electrical power flows efficiently.

● Low Resistance: Busbars offer a large surface area for current to travel through, minimizing resistance and the potential for energy loss.

● Heat Dissipation: The structure of the busbar allows heat to dissipate evenly, preventing overheating, which can cause system failures.

By minimizing energy losses and overheating, busbar systems contribute to more reliable and cost-effective power distribution in systems with high current demands.

Fault Protection and Safety Features

Busbar systems are designed not only for efficiency but also for safety. In case of electrical faults, busbars provide critical protection to ensure that the system remains functional and secure. Their robust design helps to isolate faulty sections, preventing the spread of electrical faults across the system.

● Fault Isolation: Busbars can be configured with protective devices, like circuit breakers and fuses, that quickly isolate any faulted area. This limits damage to other parts of the system.

● Sturdy Connections: The bolted connections in busbar systems ensure that there is minimal risk of loose connections, which could lead to overheating or sparking.

In addition to fault protection, busbar systems provide a higher level of safety for both operators and equipment. They are designed to prevent electrical hazards, ensuring the system operates smoothly even during fault conditions.

Tip: When designing or upgrading your power system, always prioritize busbar systems that are engineered for optimal power distribution, efficiency, and safety.

Applications of Busbar Systems

Industrial Applications

In manufacturing plants and factories, busbar systems play a critical role in efficiently distributing power to various machines and equipment. They provide a centralized, organized method for connecting high-current circuits, making installations faster and less cluttered compared to traditional wiring methods.

● Efficient Power Distribution: Busbars reduce the need for multiple cables, simplifying the electrical infrastructure.

● High Current Handling: Their ability to handle high power loads ensures reliable operation in machinery-heavy environments.

● Compact Design: Ideal for factory settings where space is limited, busbars offer a compact solution for high-capacity power distribution.

By consolidating power distribution into a single point, busbar systems improve the overall efficiency of industrial setups, reducing energy loss and maintenance costs.

Power Distribution Networks

Busbar systems are essential in power distribution networks, especially in substations and switchgear systems. They act as the central link for multiple electrical circuits, connecting transformers, circuit breakers, and other critical components in the network.

● Substations: Busbars provide a reliable, low-resistance pathway for electricity, ensuring smooth distribution from high-voltage transmission lines to lower-voltage local networks.

● Switchgear Systems: In switchgear, busbars help manage the flow of electricity across circuits, offering both redundancy and protection for the system.

Their role in these networks is critical for maintaining system reliability and safety, reducing the complexity of power management across large grids.

Renewable Energy

In renewable energy applications, such as solar farms and wind turbines, busbar systems are integral in efficiently managing and distributing the electricity generated. Their ability to handle fluctuating power loads makes them perfect for renewable energy setups, where power generation can vary throughout the day.

● Solar Farms: Busbars connect solar panels to inverters and storage systems, allowing for efficient distribution of the generated electricity.

● Wind Turbines: Similar to solar power, busbars distribute electricity from wind turbines to storage or grid systems, ensuring smooth energy flow.

● Electric Vehicle Charging Stations: Busbars ensure reliable, high-capacity distribution of power to multiple charging stations, improving the user experience and reducing downtime.

The ability to handle high currents efficiently and reduce energy loss is crucial in these green energy applications.

Commercial and Data Centers

In commercial buildings and data centers, busbar systems are used to distribute power to various circuits, servers, and equipment. They provide a space-saving and efficient solution for large-scale power distribution, ensuring that multiple systems receive the correct voltage and current.

● Large Buildings: Busbars help manage power distribution across different floors or departments, streamlining the infrastructure.

● Server Farms: Data centers rely on busbar systems to manage high power demands and ensure uptime. Their compact and reliable design allows for smooth operation even under heavy electrical loads.

In both commercial and data center environments, busbar systems ensure that electricity is distributed safely and efficiently to support critical infrastructure.

Design Considerations for Busbar Systems

Sizing and Current Rating

When designing a busbar system, one of the most important factors to consider is sizing. It’s crucial to select a busbar with the correct current rating to ensure safe and efficient power distribution. If the busbar is undersized, it may overheat or fail under high loads. On the other hand, oversized busbars may lead to unnecessary costs and inefficient use of space.

● Calculating Current Needs: Busbars should be sized based on the maximum expected current load. It’s essential to take into account the peak load, any future expansion needs, and the safety margins for electrical systems.

● Safety Margin: A safety margin is crucial to account for variations in load and environmental factors like temperature and humidity, which could affect the busbar's performance.

Selecting the right size ensures that the busbar system operates within its capacity, improving reliability and reducing maintenance costs.

Thermal Management

Effective thermal management is a key consideration when designing busbar systems. As electricity flows through the busbars, it generates heat, and if not properly managed, this heat can lead to overheating, which may damage the busbar system or reduce its lifespan.

● Heat Dissipation: Busbars are often designed to have large surface areas, which helps dissipate heat. Proper heat distribution prevents localized hot spots, which can cause failures.

● Cooling Systems: In some high-load applications, additional cooling systems, such as air conditioning or liquid cooling, may be necessary to maintain the optimal operating temperature.

Maintaining an efficient thermal management system ensures that the busbar system remains functional, safe, and durable over time.

Space and Layout

The layout and space requirements of a busbar system are especially important in high-density installations. In environments such as data centers, factories, or substations, space is often at a premium, and a well-designed busbar system helps save valuable room while ensuring that the system remains effective.

● Compact Design: Busbars offer a more compact alternative to traditional wiring, reducing the amount of space needed for power distribution. This is particularly useful when dealing with space constraints in industrial or commercial setups.

● Layout Efficiency: The system layout should be planned to allow for easy access for maintenance and future upgrades. Additionally, the busbars should be positioned to minimize the length of electrical paths, reducing resistance and improving efficiency.

A thoughtful layout can maximize space while ensuring the system’s reliability and scalability.

Safety Standards and Compliance

When designing busbar systems, it's critical to comply with safety standards and regulatory requirements to ensure the system operates safely and meets industry norms. These standards not only ensure safety but also help maintain reliability, especially in high-risk environments.

● Regulatory Compliance: Busbars must adhere to local and international electrical safety standards such as IEC (International Electrotechnical Commission) and UL (Underwriters Laboratories).

● Protection Features: Design features like circuit breakers, fault isolation, and proper insulation help ensure that the busbar system remains safe under various operating conditions.

Ensuring compliance with safety regulations is essential to prevent accidents, system failures, and ensure long-term durability of the busbar system.

Advantages of Busbar Systems

Simplified Installation

Busbar systems eliminate the need for numerous wires, making installation faster and more straightforward. Their modular design also allows for easy adjustments as the system evolves.

High Current Capacity

With a larger surface area, busbar systems can handle high currents with minimal energy loss, making them perfect for industrial and commercial applications that require significant power.

Cost Efficiency

While the initial cost of busbar systems may be higher than traditional wiring, they provide long-term savings. Their reduced maintenance needs and durability make them a cost-effective solution over time.

Flexibility and Scalability

Busbar systems can be easily scaled to accommodate growing power needs. Whether it’s expanding an industrial facility or upgrading a power network, busbars provide the flexibility to modify and expand systems as necessary.

Enhanced Safety

Busbars improve the overall safety of electrical systems by reducing the risks associated with wiring failures. Their sturdy construction ensures reliable connections, even under high power demands.

Challenges and Disadvantages of Busbar Systems

Initial Cost

The upfront investment in busbar systems can be higher than traditional wiring systems due to the cost of materials and installation. However, this cost is often offset by the long-term savings in maintenance and power efficiency.

Complexity in Some Configurations

Certain busbar systems, like the ring busbar, can be complex to design and install. These systems require specialized knowledge to ensure they function efficiently and safely.

Space Requirements

While busbar systems save space in comparison to traditional wiring, large installations may require considerable space. The physical footprint of the system should be considered in high-density environments.

Maintenance Needs

While busbars require less maintenance than traditional wiring, some configurations, particularly double busbar setups, need frequent inspections to ensure continued performance and safety.

Choosing the Right Busbar System for Your Application

Evaluating Power and Voltage Requirements

When selecting a busbar system, it's crucial to evaluate the specific voltage and current requirements of your system. This will determine the size, material, and configuration of the busbar.

Material and Budget Considerations

Choosing between copper and aluminum depends on both performance needs and budget. Copper is ideal for high-performance applications, while aluminum provides a more budget-friendly solution for large systems.

Space Constraints and Installation Environment

Consider your system’s available space and environmental conditions when selecting a busbar system. Flexible and compact designs may be required for tight spaces, while larger systems may accommodate rigid busbars with higher current capacity.

Conclusion

Busbar systems are crucial in modern electrical setups, offering efficient and scalable solutions for power distribution. Understanding the different types of busbars, their benefits, and the factors to consider will help you choose the best system for your needs. Whether used in industrial, renewable, or commercial applications, busbars optimize power flow and reduce complexity.

Hongmao offers high-quality busbar systems designed to provide reliable and cost-effective solutions for various applications, enhancing efficiency and safety in your electrical installations.

FAQ

Q: What are busbar systems?

A: Busbar systems are conductive pathways that distribute electrical power within a system. They efficiently consolidate multiple connections and are used in power grids, industrial plants, and renewable energy setups.

Q: How do busbar systems work?

A: Busbar systems distribute electricity across various circuits from a central point, minimizing energy loss and improving overall efficiency by providing a low-resistance path for power flow.

Q: Why are busbar systems preferred in industrial applications?

A: Busbar systems are preferred in industrial applications due to their high current capacity, space-saving design, and ability to simplify complex power distribution networks.

Q: What are the advantages of using busbar systems?

A: Busbar systems reduce wiring complexity, handle high power loads with minimal energy loss, save space, and improve overall safety, making them ideal for large-scale electrical installations.

Q: How do I choose the right busbar system for my project?

A: When selecting a busbar system, consider factors like voltage and current requirements, available space, and material (copper vs. aluminum) to ensure the optimal solution for your power distribution needs.