Introduction

Have you ever wondered how large power systems manage to distribute electricity so efficiently? The answer often lies in electrical busbars—a key component in modern power systems.

In this article, we'll explore what electrical busbars are, how they function, and why they're essential in systems ranging from power plants to renewable energy sources. You'll learn about their advantages, potential drawbacks, and how to choose the right busbar for your needs.

What Are Electrical Busbars?

Definition and Functionality

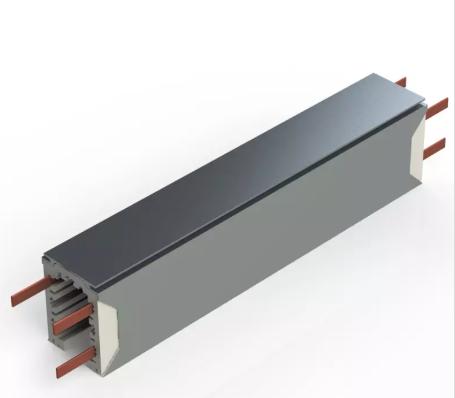

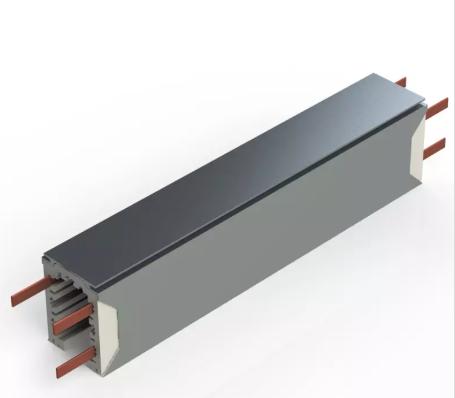

An electrical busbar is a metallic strip, tube, or rod that conducts electrical power within a system. It serves as a central link for multiple incoming and outgoing electrical circuits, distributing electricity across various components efficiently. Unlike traditional wiring, which can become bulky and inefficient for large-scale systems, busbars provide a neat and space-saving solution.

Busbars are typically made from high-conductivity materials such as copper or aluminum, ensuring minimal resistance and energy loss. Their primary function is to facilitate the safe and efficient transfer of electricity within high-current systems, such as substations, switchboards, and industrial machines.

Physical Characteristics

Busbars come in various shapes and sizes depending on the application. They can be flat, round, or flexible. The most common types are:

● Rigid Busbars (Flat bars): These are the most widely used and are typically manufactured to fit specific needs. They provide a large surface area for better heat dissipation.

● Round Busbars: These are used in applications where rigidity and flexibility are required. They are also ideal for high-current applications.

● Flexible Busbars: Made from laminated thin metallic strips, flexible busbars offer high conductivity and are used in compact or irregular configurations.

How Busbars Work in Electrical Systems

Electrical busbars work by providing a low-impedance path for electrical current to flow. They allow multiple power sources to connect at a single point and distribute the electricity efficiently to various devices. The design of a busbar ensures that the current flows evenly along its length, preventing any significant voltage sag or energy loss.

Example: In industrial machinery, a busbar system might connect a high-voltage power supply to a series of machines, ensuring that each machine receives the correct power while minimizing wiring complexity.

Common Applications of Electrical Busbars

Power Distribution Systems

Electrical busbars are integral to power distribution systems, especially in substations, switchgear, and distribution panels. They efficiently distribute power across various circuits, providing a central point for connections.

● Substations: Busbars serve as the backbone of power distribution in substations, connecting transformers, circuit breakers, and other equipment.

● Switchgear: In switchgear systems, busbars help distribute electrical power to various components, ensuring safe and reliable operation.

Renewable Energy Systems

In solar and wind energy applications, busbars help manage the distribution of electricity generated by renewable sources. Their ability to handle high currents and minimize energy loss makes them ideal for renewable energy installations, where efficiency is crucial.

● Solar Farms: Busbars connect solar panels to inverters and batteries, distributing the generated power efficiently.

● Wind Turbines: In wind energy systems, busbars connect the turbine generators to power grids or energy storage systems.

Industrial and Commercial Use

In industrial facilities, busbars are used for power distribution to various machines and equipment. Their high current-handling capacity and space-saving design make them a preferred choice in factories, data centers, and large commercial buildings.

● Manufacturing Plants: Busbars are used to distribute electricity to various production lines and machinery.

● Data Centers: In data centers, where high current and minimal space are crucial, busbars provide an efficient way to manage power.

Battery and Energy Storage

Busbars are also crucial in battery power distribution systems, especially for electric vehicles (EVs) and large-scale energy storage applications. They are used to interconnect battery packs, ensuring a reliable and efficient flow of electricity.

Example: In EVs, busbars connect the battery cells to the inverter, ensuring power is distributed evenly and efficiently.

Types of Electrical Busbars

By Material

● Copper Busbars: Copper is the most commonly used material for busbars due to its excellent electrical conductivity. It provides minimal energy loss and is highly durable, making it ideal for high-performance systems. However, copper is expensive and heavier compared to aluminum.

● Aluminum Busbars: Aluminum busbars are lighter and more cost-effective than copper. While they have slightly lower conductivity, aluminum's lower weight and lower cost make it a popular choice for larger systems, especially where space and budget are limited.

By Shape

● Flat Busbars: These busbars are rectangular in shape and provide a large surface area for heat dissipation. They are commonly used in switchgear and industrial machinery.

● Round Busbars: These busbars are used in applications that require flexibility and higher current-carrying capacity. They are typically used for high-current applications where rigidity and rotation are necessary.

● Flexible Busbars: These are ideal for irregular layouts and tight spaces. Their flexible nature makes them easier to install in environments with complex geometries.

By Voltage Type

● Single-phase Busbars: These busbars are used in systems that require a single-phase current. They typically have two conductors: one live and one neutral.

● Three-phase Busbars: Three-phase busbars are used in industrial systems, providing three separate conductors for each phase of the electrical current. They are more efficient for distributing large amounts of power.

Advantages of Electrical Busbars

Simplified Power Distribution

Electrical busbars significantly reduce the complexity of power distribution systems. By consolidating multiple electrical connections into a central hub, busbars eliminate the need for a tangled mess of individual wires. This centralization makes the entire system cleaner, easier to manage, and more organized, particularly in large setups like industrial facilities or power plants.

● Centralized Connections: Instead of connecting each device separately, busbars offer one point for all connections, simplifying installation and maintenance.

● Reduction in Wiring Complexity: With busbars, the need for numerous wires is eliminated, which makes both the design and upkeep of systems much more straightforward.

High Current Handling Capacity

One of the standout benefits of electrical busbars is their ability to handle high currents with minimal loss. Their large surface area allows them to carry more electrical current without significant resistance or overheating, making them ideal for high-load applications.

● Low Resistance: Busbars offer a low-impedance path, minimizing voltage drops and reducing energy losses.

● Minimal Energy Loss: Their efficient design ensures that most of the energy generated reaches its destination, especially in high-load environments.

Space and Cost Efficiency

In comparison to traditional wiring systems, busbars are compact and efficient, saving valuable space and reducing costs. Their design allows for a more organized and efficient layout, even in complex systems.

● Compact Design: Busbars require less space than a large bundle of cables, allowing for better organization and utilization of space.

● Cost-Effective Installation: Installation is quicker and more affordable because fewer components are needed compared to a conventional wiring system.

Flexibility and Scalability

Electrical busbars provide flexibility, making it easy to adapt or expand your system. Their modular nature allows for easy adjustments, whether you need to modify existing connections or expand to meet growing power demands.

● Easy to Adapt: As needs change, busbars can be easily adjusted or reconfigured to accommodate new equipment or additional circuits.

● Scalable: Whether it's expanding a small facility or upgrading a large system, busbars can scale to handle increased power distribution without significant redesigns.

Enhanced Reliability and Safety

Busbars improve the safety and reliability of electrical systems. With sturdy, bolted connections and solid construction, busbars are less prone to loosening and are built to withstand high currents.

● Sturdy, Bolted Connections: Unlike cables, busbars use bolted connections that offer a more secure and reliable electrical link.

● Improved Fault Protection: In case of a fault, busbars provide better protection by isolating faulty circuits more efficiently than traditional wiring, preventing system-wide disruptions.

Disadvantages of Electrical Busbars

Initial Cost

One of the biggest drawbacks of electrical busbars is the higher upfront cost. Unlike traditional wiring systems, busbars require a significant initial investment. The materials, manufacturing process, and installation can be more expensive, especially for copper busbars, which are priced higher than aluminum.

● Upfront Investment: Busbars may seem costly when compared to standard wiring, due to their specialized materials and design.

● Material and Labor Costs: Copper, being a premium conductor, increases costs significantly. Additionally, skilled labor is required for installation, adding to the overall expense.

Complexity in Certain Configurations

While busbars are generally easy to install, certain configurations—such as ring busbar setups—can be technically demanding. These systems require careful planning to ensure optimal current distribution and avoid issues like circulating currents, which can lead to inefficiencies.

● Ring Busbar Systems: These configurations offer redundancy but are more complicated to design and maintain.

● Specialized Knowledge: Engineers need to ensure that the system is correctly sized and configured, requiring specific expertise.

Space Requirements

Busbars can be bulkier than traditional wiring, especially in high-current applications. As a result, larger installations may require more physical space than cables would. While busbars save space by consolidating multiple connections, they might still demand considerable room in larger systems, such as those found in industrial settings.

● Large-Scale Systems: Busbars might occupy more space, particularly when handling high currents or complex setups.

● Additional Support Structures: Some busbar systems, especially those involving copper, may require additional structural support to ensure stability and avoid sagging.

Maintenance Challenges

Busbars are relatively low-maintenance compared to wiring systems, but certain configurations, especially double busbar systems, can demand more attention. These systems, which involve multiple busbars for redundancy, require regular inspections to ensure that they function correctly and safely.

● Frequent Inspections: Double busbar setups need frequent checks for tightness and integrity to avoid any faults.

● Wear and Tear: Over time, even well-maintained systems can develop issues like corrosion or overheating, requiring maintenance or replacement of parts.

Busbar Design and Installation Considerations

Design Factors

When designing a busbar system, several factors must be considered to ensure optimal performance and safety. Balancing current capacity, thermal performance, and space efficiency is crucial. The design should handle the required power load while minimizing energy losses, ensuring that the system can operate efficiently even under high currents.

● Current Capacity: The busbar must be able to carry the required electrical current without excessive heat buildup. This involves selecting the right material and ensuring the busbar has the appropriate size and cross-sectional area.

● Thermal Performance: Busbars generate heat due to electrical resistance. Adequate cooling and heat dissipation are necessary to prevent overheating. Properly designed busbars ensure that heat is evenly distributed and doesn't compromise the system's safety.

● Space Efficiency: Busbars need to fit into tight spaces, particularly in industrial or commercial settings. The design should prioritize compactness without compromising current-carrying capacity or thermal performance.

Installation Process

The installation of electrical busbars involves several key steps to ensure that the system is both functional and safe. The process includes mounting, joint assembly, and connection to equipment.

● Mounting: Busbars are typically mounted on insulators or support brackets, ensuring they remain secure and properly spaced. The mounting system must be stable enough to prevent sagging or movement under load.

● Joint Assembly: When connecting busbars, the joints must be carefully assembled to minimize electrical resistance. Common methods include bolting, clamping, or welding the busbar ends together. Proper torque must be applied to ensure tight, secure connections.

● Connection to Equipment: Once the busbars are securely mounted and assembled, they are connected to electrical equipment like transformers, switchgear, or circuit breakers. These connections need to be well-designed to handle the electrical load and prevent damage over time.

Maintenance and Monitoring

While busbars are low-maintenance, regular monitoring is essential to ensure their longevity and optimal performance. There are several best practices that should be followed for busbar upkeep.

● Thermal Scanning: Using thermal cameras to scan busbars can help identify potential hot spots, which may indicate loose connections or excessive resistance. Addressing these issues early can prevent overheating and system failure.

● Bolt Tightness Checks: Busbars use bolted connections, which can loosen over time due to thermal expansion and contraction. Regular inspections of bolt tightness are essential to prevent electrical faults or dangerous overheating.

● Cleaning and Insulation Checks: Dust and contaminants can accumulate on busbars, reducing their efficiency and heat dissipation. Regular cleaning and checking the insulation's condition help ensure that the system is operating safely and effectively.

Choosing the Right Busbar for Your System

Evaluating Voltage and Current Needs

When selecting a busbar, one of the most critical factors to consider is the system’s voltage and current requirements. The busbar must be able to safely carry the electrical load without overheating or excessive resistance. Understanding the specific power demands of your system will help determine the right material and configuration for optimal performance.

● Material Selection: If your system requires high current handling, copper is usually the preferred choice due to its excellent conductivity. However, for systems where weight and cost are major concerns, aluminum might be the better option despite its slightly lower conductivity.

● Configuration: Depending on whether the system requires single-phase or three-phase current, you’ll need to choose a busbar that meets the required power distribution needs. Three-phase busbars generally have a larger capacity to handle higher loads.

Considering Space and Budget

Space and budget are also crucial when choosing a busbar. While busbars are space-efficient compared to traditional wiring systems, larger installations, such as those in industrial settings, may require busbars with a larger cross-sectional area.

● Space Constraints: For tight spaces, you may need to choose a compact busbar design, like flexible busbars. On the other hand, larger installations might accommodate rigid busbars that offer higher current capacity but take up more space.

● Cost Considerations: Copper busbars are typically more expensive than aluminum ones. While copper provides superior performance in terms of conductivity and heat dissipation, aluminum is a more cost-effective solution, especially for large systems.

Selecting for Specific Applications

Busbars are highly versatile and can be tailored for specific applications. Whether you are working on a renewable energy system, industrial power setup, or commercial facility, selecting the right busbar ensures maximum efficiency and safety.

● Renewable Energy: For solar or wind power systems, flexible busbars are often the best choice due to their adaptability and ability to handle fluctuating power loads.

● Industrial Use: In factories or manufacturing plants, rigid copper busbars are ideal for distributing high currents to machinery, ensuring reliability and durability.

● Commercial Systems: In commercial buildings, especially those with multiple circuits, aluminum busbars provide a cost-effective, lightweight solution for efficient power distribution.

Conclusion

Electrical busbars play a crucial role in modern power distribution systems. They provide a more efficient, reliable, and cost-effective alternative to traditional wiring. When designing a power distribution system, whether for a factory, renewable energy setup, or data center, understanding the benefits of busbars is essential.

Busbars, with their high current capacity, space efficiency, and adaptability, are key components for any modern electrical installation. By considering factors like power demands, space, and budget, you can select the ideal busbar solution.

Hongmao offers high-quality electrical busbars that ensure optimal performance and value. Their products are designed to meet the diverse needs of various applications, providing reliable and efficient power distribution solutions.

FAQ

Q: What are electrical busbars?

A: Electrical busbars are metallic strips or rods used for power distribution. They consolidate electrical connections in a system, offering a more efficient and space-saving alternative to traditional wiring.

Q: How do electrical busbars work?

A: Electrical busbars distribute electrical power by acting as a central hub for multiple circuits. They carry high currents efficiently, minimizing energy loss and heat generation in power systems.

Q: Why are electrical busbars used in industrial applications?

A: Electrical busbars are commonly used in industrial applications due to their high current handling capacity, compact design, and ability to simplify complex power distribution systems.

Q: What are the advantages of electrical busbars?

A: Electrical busbars offer benefits like reduced wiring complexity, better space utilization, high current capacity, and scalability for growing systems.

Q: How do I choose the right electrical busbar for my system?

A: When choosing electrical busbars, consider factors such as voltage and current requirements, available space, material (copper vs. aluminum), and budget to ensure the optimal solution for your system.