In commercial buildings, power distribution can be a challenge. Traditional wiring systems often fail to meet modern demands, causing inefficiencies.

Lighting busbar trunking systems offer a compact, scalable solution for distributing power. In this article, we’ll explore lighting busbar systems, their features, and how they outperform traditional wiring methods.

What is a Lighting Busbar Trunking System?

Definition and Basic Components

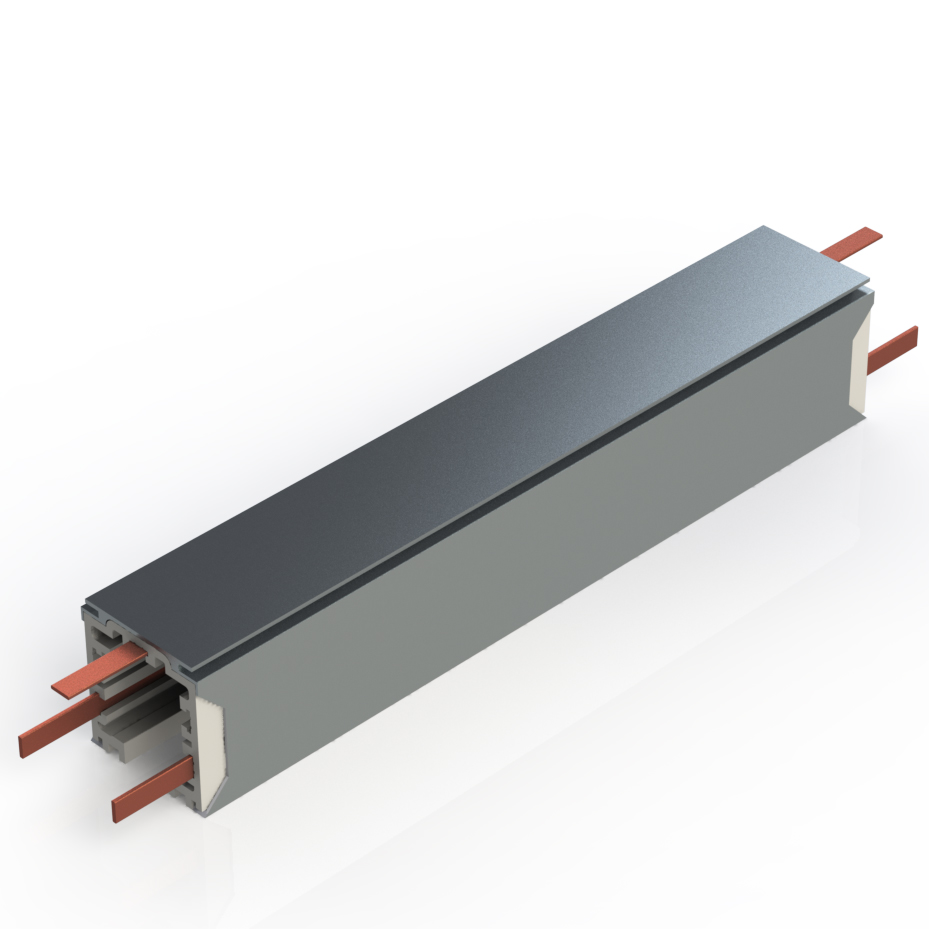

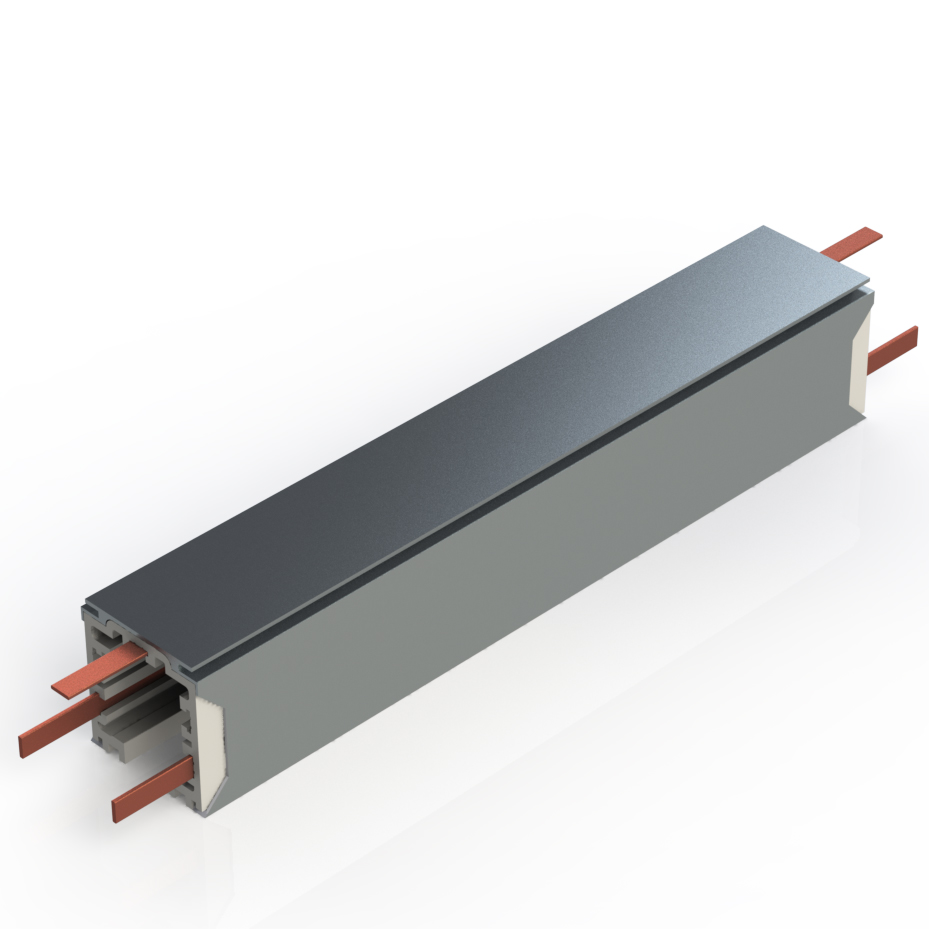

A lighting busbar trunking system (BTS) is a modern electrical distribution solution that uses conductors enclosed in a protective casing to distribute power to lighting fixtures. The system consists of several key components that work together to ensure efficient and safe power distribution:

Busbars: These are the primary conductors made of copper or aluminum, designed to carry electrical power over long distances.

Insulation: This material surrounds the busbars to prevent electrical faults and short circuits, ensuring safety.

Housing: The busbars and insulation are encased in a protective housing that shields them from physical damage and environmental factors.

Tap-off Units: These are outlets that allow the power to be distributed to different lighting circuits within a building, with plug-and-play functionality for easy connections.

By integrating these components, lighting busbar trunking systems offer a compact, safe, and flexible solution for powering lighting fixtures.

Working Mechanism of a Lighting Busbar System

The lighting busbar trunking system operates by transmitting electricity from the main electrical panel to different lighting points throughout the building. Power flows through the busbars, which are typically arranged in a modular fashion to allow for easy expansion and reconfiguration as needed.

The system’s modular design allows for quick installation and future modifications, making it highly adaptable to changing power needs. Tap-off units are placed at regular intervals along the busbar, enabling electrical power to be accessed by different lighting circuits without the need for extensive rewiring. This flexibility makes lighting busbar systems a preferred choice for environments with complex or evolving power distribution requirements.

Key Features of a Lighting Busbar Trunking System

Space Efficiency and Compact Design

One of the main advantages of a lighting busbar trunking system is its compact size. In high-density environments like offices, shopping malls, and large buildings, space is often limited. Traditional wiring systems can occupy a lot of space, requiring cable trays, conduits, and other materials to support the wiring.

Lighting busbar trunking systems require far less space. The system’s modular nature allows for seamless integration into building layouts, reducing the need for bulky wiring infrastructure. This makes it a highly efficient solution, especially in areas where space optimization is critical.

Flexibility and Scalability

Lighting busbar trunking systems are designed to be modular, meaning they can be easily expanded or reconfigured to meet changing electrical requirements. As businesses grow or building layouts evolve, it’s simple to add or remove tap-off units along the busbar without disrupting the entire system.

Moreover, the plug-and-play feature of tap-off units allows for quick modifications, minimizing downtime during system upgrades. This scalability is especially useful for growing commercial spaces, data centers, or industrial facilities that require frequent electrical reconfigurations.

Enhanced Safety Features

Safety is a key consideration in any power distribution system, and lighting busbar trunking systems are designed to reduce risks. The enclosed housing provides superior protection against external damage, reducing the risk of electrical faults, short circuits, and fires. The busbars are also insulated to prevent accidental contact with live components.

Moreover, lighting busbar systems are built with fire-resistant materials and feature better thermal management compared to traditional wiring. This minimizes the chances of overheating and electrical fires, making them a safer choice for buildings with high power loads.

In buildings where space and safety are top priorities, lighting busbar trunking systems offer a superior alternative to traditional wiring.

Advantages of Lighting Busbar Trunking Systems Over Traditional Wiring

Reduced Installation Time and Cost

Lighting busbar trunking systems significantly reduce installation time compared to traditional cable-based systems. Conventional wiring systems often require extensive labor, including the installation of cable trays, conduits, and junction boxes. In contrast, busbar systems are pre-fabricated and ready to install, minimizing the time required for setup.

The reduced installation time also translates into lower labor costs. Additionally, because busbars take up less space and require fewer materials, the overall cost of installation is often lower than traditional methods.

Improved Energy Efficiency

One of the most compelling reasons to switch to a lighting busbar trunking system is its energy efficiency. Busbars have lower electrical resistance compared to traditional cables, which means less energy is lost as heat. This results in better voltage regulation, especially in large buildings where maintaining consistent power levels across multiple circuits is essential.

The improved energy efficiency of busbar systems leads to long-term savings on energy costs, making them an environmentally and financially sustainable choice.

Long-Term Maintenance Benefits

Lighting busbar trunking systems are designed for easy maintenance. Since the system is modular, individual components like tap-off units can be easily accessed and serviced without disrupting other parts of the electrical network. This ease of access reduces maintenance time and cost.

In addition, busbar systems require fewer repairs compared to traditional wiring. They are more durable, with less risk of damage from physical strain, overheating, or accidental contact, making them a long-lasting solution for lighting power distribution.

| Feature | Lighting Busbar System | Traditional Wiring System |

| Space Efficiency | Compact design, requires less space | Bulky, requires cable trays and conduits |

| Flexibility | Modular, easy to expand and reconfigure | Difficult to modify once installed |

| Installation Time | Quick, minimal labor-intensive installation | Longer installation times due to complex setup |

| Energy Efficiency | Lower power loss, better voltage regulation | Higher power loss due to resistance |

| Safety | Superior insulation, reduced fire risks | Higher fire risk and potential short circuits |

| Maintenance | Easy to inspect and maintain | More challenging maintenance and repairs |

| Scalability | Easily scalable for future expansions | Limited scalability without major rewiring |

| Cost | Initial cost may be higher, but offers long-term savings | Lower initial cost, but higher long-term costs |

Applications of Lighting Busbar Trunking Systems

Commercial Buildings and Offices

Lighting busbar trunking systems are ideal for commercial buildings like office complexes, retail stores, and high-rise buildings. The modular and compact design allows for efficient power distribution to lighting fixtures across multiple floors or sections of a building. This is especially important in buildings with complex layouts or high foot traffic, where flexibility and space-saving solutions are crucial.

Industrial Facilities

In industrial facilities such as factories and warehouses, lighting busbar trunking systems can power lighting circuits, overhead machinery, and other electrical loads. These systems are well-suited for environments with high power demands, offering efficient energy transmission and a safer alternative to conventional wiring.

Public Spaces and High-Traffic Areas

Lighting busbar systems are also commonly used in public spaces like airports, shopping malls, and sports arenas. These areas often require large amounts of lighting, and the flexibility of busbar systems allows for easy reconfiguration to accommodate changing needs. Additionally, the reduced installation time and lower space requirements make them a perfect fit for high-traffic locations.

How to Choose the Right Lighting Busbar Trunking System

Consideration of Current and Voltage Requirements

When selecting a lighting busbar trunking system, it is essential to consider the current and voltage requirements of the building. A proper system should be able to handle the total electrical load required for all lighting circuits without risk of overheating or failure.

Environmental and Installation Factors

Environmental conditions such as temperature, humidity, and exposure to corrosive elements can affect the performance of a busbar system. Ensure that the busbar system is rated for the specific conditions of the installation site. For example, buildings in coastal areas may require busbars with higher protection ratings to guard against corrosion.

Future Expansion Considerations

Consider the potential for future expansion when selecting a busbar system. Modular systems offer the flexibility to add or remove tap-off units as needed, which is ideal for growing businesses or buildings that may undergo renovations or modifications in the future.

Installation and Maintenance of Lighting Busbar Trunking Systems

Installation Process

Installing a lighting busbar trunking system involves several key steps:

Planning: Assess the building’s electrical needs and determine the optimal layout.

Component Selection: Choose the right busbar size, insulation type, and tap-off units.

Assembly: Secure the busbar sections and connect them to the main electrical panel.

Connection: Install tap-off units and ensure all connections are properly tightened and insulated.

Regular Maintenance Tips

Regular maintenance of the lighting busbar trunking system includes:

Visual Inspections: Check for signs of wear, corrosion, or loose connections.

Cleaning: Keep the busbar enclosure clean and free of debris.

Testing: Periodically test insulation resistance and check for overheating.

Regular maintenance ensures the system continues to operate efficiently and safely, extending its lifespan and reducing the risk of electrical failures.

Conclusion

Lighting busbar trunking systems provide a modern and space-efficient solution for power distribution. With their modular design, enhanced safety features, and energy efficiency, they offer significant advantages over traditional wiring. As buildings and power needs evolve, these systems ensure flexibility and scalability. For long-term cost savings and energy efficiency, lighting busbar trunking systems are a smart investment.

Wenzhou Hongmao offers high-quality lighting busbar systems, providing reliable and flexible solutions for businesses seeking efficient power distribution.

FAQ

Q: What is a lighting busbar trunking system?

A: A lighting busbar trunking system is a modern electrical solution that uses conductors enclosed in a protective casing to distribute power to lighting fixtures efficiently.

Q: How does a lighting busbar system work?

A: Power flows through the busbars, with tap-off units placed at intervals to distribute electricity to lighting circuits, allowing easy modifications and scalability.

Q: What are the benefits of using a lighting busbar?

A: Lighting busbars offer space efficiency, enhanced safety, lower installation time, and better energy efficiency compared to traditional wiring systems.

Q: Why choose a lighting busbar trunking system over traditional wiring?

A: Lighting busbars are more flexible, energy-efficient, and safer, making them ideal for modern power distribution needs and future expansions.