Introduction

Have you ever wondered how large electrical systems manage power distribution so efficiently? The answer often lies in Power Busbars—key components in modern power setups.

In this article, we’ll explore what Power Busbars are, how they work, and why they are crucial in simplifying complex electrical systems. You’ll learn about their role in improving efficiency, reducing wiring complexity, and meeting high-power demands in various industries.

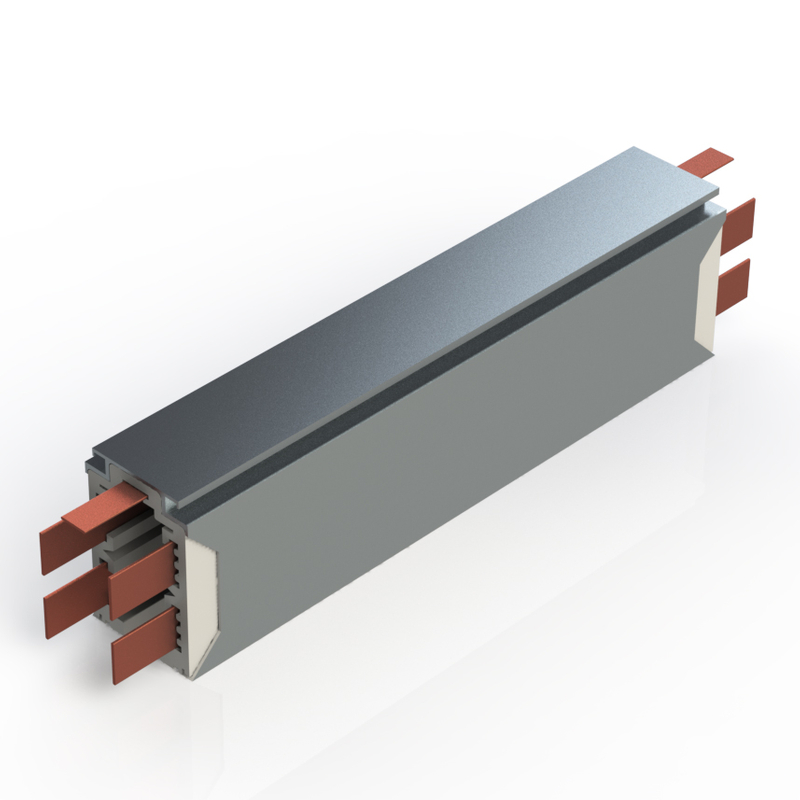

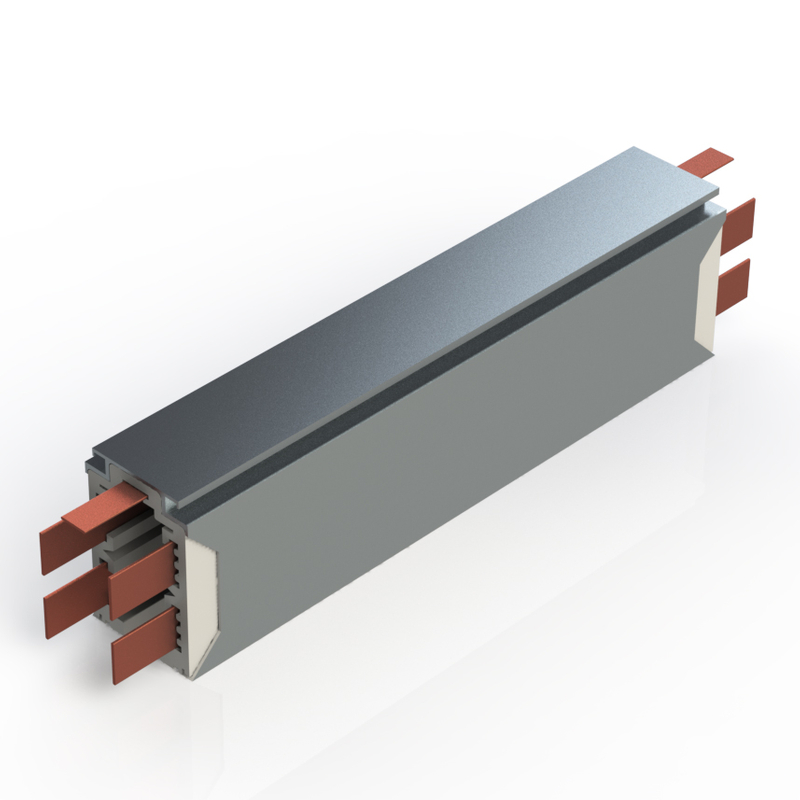

Understanding Power Busbars

Functionality and Purpose

A power busbar acts as a central conductor in an electrical system. It efficiently distributes electrical power by connecting multiple circuits through a single, centralized path. Unlike traditional wiring, which may require numerous cables and connections, a busbar simplifies the system by consolidating these connections. This not only reduces complexity but also increases the efficiency of power delivery.

In high-current environments, busbars are designed to handle large electrical loads, ensuring safe and reliable power distribution. Their ability to manage high currents makes them ideal for use in industrial and commercial power systems.

Material Choices

The materials used in power busbars directly impact their performance. The two most common materials are copper and aluminum, each offering unique benefits:

● Copper: Copper is the most widely used material for power busbars. Its superior conductivity allows for minimal energy loss and makes it ideal for high-performance applications. However, copper is more expensive and heavier compared to aluminum.

● Aluminum: Aluminum is a lightweight, cost-effective alternative. While its conductivity is lower than copper's, it is still sufficient for many applications, especially when budget or weight is a concern. Aluminum busbars are often used in larger installations where space and cost are priorities.

Each material has its place depending on the application’s performance needs and constraints.

Applications of Power Busbars

Power busbars are versatile and used in various systems to distribute power efficiently. Here are some common applications:

● Industrial Machinery: In factories and manufacturing plants, power busbars are essential for connecting heavy machinery to the power supply. Their ability to handle high current ensures that machines operate reliably without the risk of overheating or power failure.

● Data Centers: Data centers require constant, high-capacity power. Power busbars provide a streamlined method to distribute power to multiple servers and systems, reducing wiring complexity and improving space efficiency.

● Electrical Distribution Systems: Busbars are key components in substations and electrical grids, ensuring safe and efficient distribution of electricity from high-voltage transmission lines to local power networks.

By consolidating connections and optimizing power flow, busbars improve the overall efficiency and reliability of electrical systems across these sectors.

Components of Power Busbars

Conductors

At the core of a power busbar system are the conductors, which are the materials that carry electrical current. The two most common materials used are copper and aluminum, each with its unique advantages.

● Copper: Copper is highly conductive, allowing for efficient transmission of electricity with minimal energy loss. This makes it the preferred choice for high-performance applications. However, copper is more expensive and heavier.

● Aluminum: Aluminum, while less conductive than copper, is lightweight and cost-effective, making it ideal for larger, budget-conscious installations. Despite its slightly lower conductivity, aluminum busbars still perform well in many applications.

The choice of conductor material directly impacts the busbar's efficiency and performance, especially in high-load environments.

Insulators

Insulators are crucial components in power busbars, ensuring that the conductive parts remain isolated and secure to prevent electrical failures. Insulation materials prevent short circuits and protect the system from unexpected power surges or faults.

The most common insulation materials include polymer-based insulators, ceramic insulators, and resin compounds, which are chosen based on their electrical resistance, temperature tolerance, and environmental conditions. Insulators are strategically placed to cover areas where conductive parts might come into contact with other components, ensuring safe operation.

Mounting Hardware

The mounting hardware used for busbars is just as important as the busbar itself. It provides the necessary support and stability to ensure the system is securely installed and performs reliably over time.

● Brackets and Supports: Busbars must be mounted on sturdy supports to keep them aligned and prevent sagging, especially in high-current environments.

● Clamps and Fasteners: These components hold the busbars in place and ensure tight, secure connections. Proper torque is required to avoid loosening, which could lead to power loss or overheating.

Proper mounting also ensures that power busbars are easily accessible for maintenance while being securely installed to meet safety and performance standards.

How Power Busbars Work

Current Distribution

A power busbar acts as the central conductor that efficiently distributes electrical power across multiple circuits. The current flows through the busbar, connecting various electrical components within the system. With its large surface area and low resistance, the busbar ensures that electrical power is delivered evenly, minimizing voltage drops and ensuring reliable operation.

By centralizing connections, power busbars simplify the wiring process and ensure that power is efficiently shared across devices, reducing the overall complexity of power distribution systems.

Minimizing Energy Losses

One of the standout benefits of power busbars is their ability to reduce energy loss compared to traditional wiring systems. Unlike cables, which often experience higher resistance and energy loss over long distances, busbars provide a direct, low-resistance path for the current to flow. This is crucial in high-power applications where energy loss can quickly add up.

● Low Resistance: Busbars' materials, like copper and aluminum, have excellent conductivity, ensuring minimal energy loss.

● Efficient Design: The busbar’s structure allows for better heat dissipation, preventing overheating that often occurs in traditional wiring.

These features help improve system efficiency, making busbars a reliable and cost-effective choice for high-current environments.

Safety Features

In addition to their efficiency, power busbars are designed with safety in mind. Several protective features, such as circuit breakers and isolators, are integrated into busbar systems to ensure the safety of both the system and the operators.

● Circuit Breakers: These devices automatically disconnect the power when an overload or short circuit is detected, preventing damage to equipment and avoiding potential hazards.

● Isolators: Isolators allow sections of the busbar system to be disconnected for maintenance or during faults, providing an extra layer of protection.

By incorporating these features, power busbars enhance the overall safety of electrical systems, making them more reliable and secure.

Advantages of Power Busbars

Simplified Power Distribution

One of the major advantages of power busbars is their ability to simplify power distribution. Traditional wiring systems can become complex and cumbersome, especially in large-scale electrical setups. With busbars, multiple electrical connections are consolidated into a single point, which not only reduces the amount of wiring needed but also makes installation more manageable.

This streamlined approach makes busbars ideal for high-demand environments, where keeping the system organized and reducing complexity is crucial. Fewer wires also reduce the risk of errors during installation and maintenance.

High Current Handling

Power busbars are designed to handle high electrical currents efficiently, making them ideal for power-hungry applications. Due to their low resistance, busbars can carry large amounts of electrical power without significant energy loss or overheating.

● Superior Capacity: Busbars can handle significantly higher currents compared to traditional wiring, making them essential for industrial machinery and high-voltage systems.

● Minimal Resistance: Their large surface area ensures a smooth and efficient path for current flow, minimizing power loss.

This makes them a preferred choice for systems requiring high reliability and performance, like factories, data centers, and power distribution networks.

Space and Cost Efficiency

Busbars help save valuable space and reduce installation costs. Their compact design allows for more efficient use of available space, especially in environments where room is limited, such as in data centers and industrial plants.

● Space-Saving Design: Busbars require less room than a bundle of traditional wires, allowing for better organization and utilization of space.

● Cost-Effective Long-Term: Though the initial investment for busbars may be higher, they offer long-term savings. Their durability and lower maintenance requirements help reduce the overall cost of ownership.

By minimizing the need for excessive wiring and reducing the footprint of power distribution systems, busbars prove to be both space-efficient and cost-effective.

Flexibility and Scalability

Power busbars provide flexibility in adapting to evolving power distribution needs. As your system grows, busbars can easily be modified or expanded to accommodate additional circuits without the need for complex redesigns.

● Adaptability: Busbar systems can be quickly adjusted to meet the increasing power demands of a growing business or facility.

● Scalability: Whether you are upgrading an existing system or building a new one, busbars can scale to meet future needs without requiring major system overhauls.

This scalability makes busbars an ideal choice for industries and facilities anticipating growth or changes in their power needs.

Disadvantages of Power Busbars

Initial Investment

While power busbars offer many benefits, one of their main drawbacks is the higher upfront cost compared to traditional wiring systems. The materials used, like copper or aluminum, can be more expensive, and the installation process requires specialized labor.

● Cost of Materials: Copper, in particular, is a premium conductor, increasing the overall cost of busbar systems.

● Labor Costs: Installation of busbars can be more complex, requiring skilled technicians to ensure proper setup and safety.

Although the initial investment is higher, the long-term savings in maintenance and efficiency may offset these costs.

Complex Installations

In some configurations, such as multi-busbar setups or ring bus configurations, the installation of power busbars can become technically challenging. These setups require careful planning and expertise to ensure that they operate efficiently and safely.

● Ring Bus Systems: These systems offer redundancy but require more advanced engineering and precision to prevent issues like circulating currents, which could lead to inefficiency.

● Installation Complexity: Unlike traditional wiring, which is simpler to install, busbars may require additional components, support structures, and more detailed design work.

The technical complexity can make installation more time-consuming and costly, especially for larger, more intricate systems.

Space Requirements

Although power busbars are space-efficient compared to traditional wiring in some scenarios, larger installations may require more physical space. This is particularly true when busbars are designed to handle high currents.

● Physical Footprint: Busbars, especially those used for high-power applications, may take up more room than bundled wires.

● Space Considerations: In confined spaces or high-density environments, busbar systems might be harder to integrate without taking up significant space.

This increased space requirement can be a limitation in environments where space is already at a premium, such as in data centers or dense industrial setups.

Maintenance Needs

While power busbars require less maintenance than traditional wiring systems, certain configurations, particularly double busbar setups, may need more frequent checks and servicing.

● Double Busbar Systems: These systems offer redundancy, but their complexity demands more regular inspections to ensure the connections are secure and functioning properly.

● Wear and Tear: Over time, components like insulators or mounting hardware may degrade and require replacement, especially in high-load environments.

Routine maintenance is essential to ensure that the busbar system continues to perform efficiently and safely over time.

Design Considerations for Power Busbars

Sizing and Current Rating

When designing a power busbar system, selecting the correct size and current rating is essential for ensuring optimal performance. The busbar must be able to handle the maximum expected electrical load without overheating or suffering damage.

● Sizing: A busbar should have the appropriate cross-sectional area to carry the current efficiently. Undersized busbars may overheat, while oversized busbars can lead to unnecessary costs.

● Current Rating: The busbar must match the system's voltage and current requirements. Understanding the system’s peak load, future growth, and safety margins ensures proper sizing for long-term performance.

Choosing the correct size and rating improves both safety and efficiency, preventing energy loss and reducing the risk of system failures.

Thermal Management

Effective thermal management is critical in high-current power busbar systems. As electrical current flows through the busbar, heat is generated due to resistance. If not managed properly, excessive heat can cause damage to the system.

● Heat Dissipation: Busbars are often designed with larger surface areas to facilitate heat dissipation. Materials like copper and aluminum are excellent conductors of heat, helping to evenly distribute the temperature across the busbar.

● Cooling Systems: For high-load applications, additional cooling measures, such as air conditioning or liquid cooling, may be necessary to maintain the busbar’s optimal operating temperature and prevent overheating.

Thermal management is a key factor in the longevity and safety of power busbar systems.

Space and Layout

The space and layout of a power busbar system are crucial, especially in high-density installations like data centers, industrial plants, and commercial buildings. An optimized layout allows for better organization, reducing clutter and improving accessibility.

● Compact Design: Power busbars take up less space than a bundle of traditional wiring, making them an excellent choice for tight or high-density spaces.

● Efficient Layout: The busbar system should be designed to minimize the distance between components, reducing resistance and energy loss. Additionally, it’s essential to leave space for future upgrades or expansion.

An efficient layout maximizes the available space while ensuring the busbar system functions efficiently and safely.

Safety Standards and Compliance

Safety standards and compliance are vital in the design and installation of power busbars. Adhering to these standards ensures that the system operates safely and meets industry requirements.

● Regulatory Compliance: Busbars must meet both local and international electrical safety standards, such as IEC (International Electrotechnical Commission) or UL (Underwriters Laboratories) guidelines. These standards guarantee that the busbar system can handle electrical loads safely without posing a risk to people or equipment.

● Protection Features: Design elements like circuit breakers, isolators, and protective barriers are incorporated into the busbar system to provide additional safety and prevent electrical hazards.

Ensuring that busbars meet safety standards is crucial for long-term reliability and protection against electrical failures.

Choosing the Right Power Busbar

Evaluating Voltage and Current Needs

When selecting the right power busbar, understanding your system’s voltage and current requirements is essential. A busbar must match the electrical needs of your system to ensure efficient and safe power distribution.

● Voltage Requirements: The busbar should be designed to handle the voltage levels within your system, whether single-phase or three-phase. Higher voltage systems may require specific configurations or materials.

● Current Capacity: The busbar must be sized to carry the maximum expected current. An undersized busbar will overheat, while an oversized one may lead to unnecessary costs.

Correctly evaluating your system’s voltage and current requirements ensures optimal performance and minimizes risk.

Material and Budget Considerations

Selecting the right material is crucial for balancing performance and cost. The most common materials for power busbars are copper and aluminum, each with distinct advantages and drawbacks.

● Copper: Known for its superior conductivity, copper busbars offer minimal energy loss and excellent heat dissipation. However, copper is more expensive and heavier than aluminum, making it better suited for high-performance applications.

● Aluminum: Aluminum is lighter and more cost-effective. While its conductivity is lower than copper, it is often chosen for larger systems where weight and budget are primary concerns.

Understanding material differences helps you choose a busbar that meets both your technical and budgetary requirements.

Space Constraints and Installation Environment

When designing a power busbar system, space constraints and the installation environment are key factors to consider. A well-designed busbar system saves space and ensures efficient power distribution.

● Space Efficiency: Busbars take up less space compared to traditional wiring systems, especially in high-density environments like data centers and factories.

● Environmental Conditions: The installation environment—whether it’s in a high-temperature, humid, or harsh industrial setting—affects the material and configuration choice. Busbars designed for these environments need adequate insulation and protection.

Tailoring the busbar system to fit your space and environmental conditions ensures smooth operation and future scalability.

Conclusion

Power Busbars are essential in modern electrical systems, providing efficient and scalable solutions for power distribution. The right materials and design ensure optimal performance while reducing wiring complexity. By incorporating Power Busbars, systems can achieve enhanced efficiency and reliability.

For high-quality solutions, consider Hongmao, a trusted provider of power busbar systems that guarantee safety, performance, and cost-effectiveness in your electrical setups.

FAQ

Q: What is a Power Busbar?

A: A Power Busbar is a conductive system used to distribute electrical power within an installation. It serves as a central hub for electrical circuits, providing a safe and efficient path for power distribution.

Q: How does a Power Busbar work?

A: Power Busbars allow electrical current to flow through multiple circuits from a single central point. They ensure minimal energy loss and prevent overheating by offering low resistance paths for power distribution.

Q: Why should I use a Power Busbar?

A: Power Busbars simplify wiring systems, reduce space usage, and improve efficiency. They handle high currents effectively, making them ideal for large-scale electrical systems such as industrial plants and power distribution networks.

Q: What materials are used in Power Busbars?

A: Power Busbars are typically made of copper or aluminum. Copper provides better conductivity, while aluminum offers a cost-effective solution, making it ideal for large installations.

Q: Are there any disadvantages to Power Busbars?

A: While Power Busbars offer significant advantages, they can be more expensive initially than traditional wiring systems. They also require careful installation and regular maintenance, especially in high-current setups.