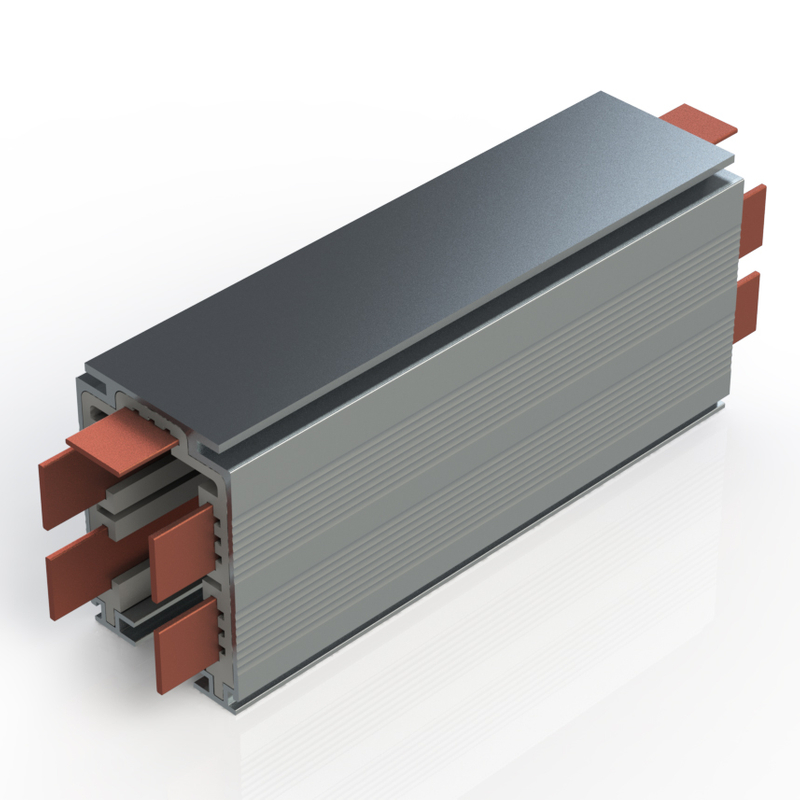

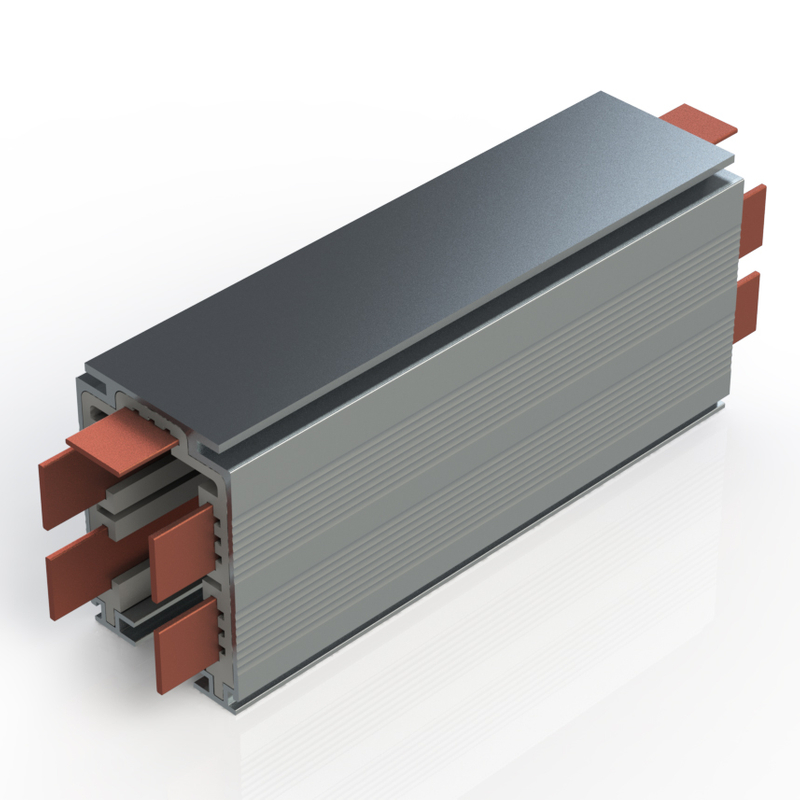

Have you ever wondered how electricity flows seamlessly through power systems? It's all thanks to power busbars. These essential components distribute electrical power efficiently, ensuring stability and reliability. But what exactly is a power busbar, and why are they so crucial in power systems? In this post, you'll learn about different types of busbar arrangements and their importance in maintaining a robust power infrastructure.

Single Bus-Bar Arrangement

Overview of Single Bus-Bar Arrangement

The single bus-bar arrangement is the simplest type used in power systems. It consists of just one bus-bar running the entire length of the switchboard. All generators, transformers, and feeders connect directly to this single bus-bar. Circuit breakers control each generator and feeder, while isolators allow maintenance by disconnecting parts from the bus-bar safely.

This design keeps things straightforward and easy to operate. It is commonly found in small power stations, switchboards, and medium-sized substations where simplicity and cost-saving matter most.

Advantages and Disadvantages

Advantages:

● Low Initial Cost: Fewer components mean less upfront spending.

● Less Maintenance: Simpler layout reduces upkeep efforts.

● Easy Operation: Operators find it straightforward to manage.

Disadvantages:

● Single Point of Failure: A fault on the bus-bar cuts off the entire supply.

● No Flexibility: Maintenance on any section requires shutting down the whole system.

● Limited Reliability: Not suitable where continuous power is critical.

Applications in Power Systems

This arrangement suits places where power interruptions are acceptable during maintenance or faults. Small substations, rural power stations, and industrial sites with backup systems often use single bus-bar setups. It works well when budget constraints outweigh the need for high reliability.

For example, a small manufacturing plant with limited power needs might use this arrangement to keep costs low. However, a hospital or data center would avoid it due to the risk of total power loss.

Single Bus-Bar Arrangement with Sectionalization

How Sectionalization Improves Reliability

Sectionalization divides the single bus-bar into smaller parts using circuit breakers or isolators. This design helps isolate faults to just one section, preventing a full system shutdown. If a fault occurs, only the affected section is disconnected, while the rest of the bus-bar keeps supplying power. This improves overall system reliability and reduces downtime.

Sectionalization also allows maintenance on one section without stopping the entire power supply. Operators can safely isolate a section for repairs while other sections continue running. This flexibility is crucial in larger substations where continuous supply matters.

Additionally, sectionalization helps manage fault currents better. By adding current-limiting reactors between sections, the fault level is reduced. This allows using circuit breakers with lower ratings, saving costs and enhancing protection.

Benefits and Drawbacks

Benefits:

● Improved Reliability: Faults stay confined to one section, avoiding total power loss.

● Maintenance Flexibility: One section can be shut down for repairs without affecting others.

● Cost-Effective: Only one extra circuit breaker is needed, keeping costs low.

● Better Fault Management: Current limiting reactors reduce fault currents.

Drawbacks:

● Slightly Higher Cost: Additional circuit breakers and isolators add expense.

● Complexity: More components mean more complexity in operation and maintenance.

● Isolator Limitations: Using air-break isolators instead of circuit breakers for sectionalizing can cause sparking if operated under load.

Typical Use Cases

This arrangement is common in large generating stations and medium to large substations. It suits systems where some level of reliability is needed but full redundancy is not justified by cost.

For example, a regional power substation serving multiple feeders may use sectionalization to keep parts of the network live during faults or maintenance. It balances cost and reliability well.

In industrial plants with several power units, sectionalization allows isolating faulty sections without halting the entire plant. This keeps production running smoothly.

Main and Transfer Bus Arrangement

Structure and Functionality

The main and transfer bus arrangement uses two bus-bars: the main bus and the transfer bus, which acts as an auxiliary. Each generator or feeder can connect to either bus through a bus coupler. This coupler includes a circuit breaker and isolating switches, letting operators switch loads between buses under load conditions.

To transfer load from the main bus to the transfer bus, operators typically:

1. Close the bus coupler circuit breaker, connecting both buses at the same voltage.

2. Close isolators on the transfer bus.

3. Open isolators on the main bus.

This process shifts the load to the transfer bus, allowing maintenance or fault isolation on the main bus without interrupting supply.

Pros and Cons

Advantages:

● Continuity of Supply: If a fault occurs on the main bus, the entire load can transfer to the transfer bus, keeping power flowing.

● Maintenance Flexibility: Operators can perform repairs on one bus while the other carries the load.

● Load Supply Options: Each load can connect to either bus, increasing operational flexibility.

● Reduced Maintenance Costs: Testing and maintenance can occur without shutting down the whole system.

● Improved Relay Operation: Bus potential supports relay functions effectively.

Disadvantages:

● Higher Initial Cost: Two bus-bars and additional switching equipment increase expenses.

● System Vulnerability: If a line fault occurs during bus transfer, it may lead to a complete station shutdown.

● Increased Complexity: More components mean more complex operation and maintenance.

Where It is Commonly Used

This arrangement suits power systems demanding high reliability and flexibility. You often find it in:

● Large generating stations.

● Substations with interconnected networks.

● Facilities requiring continuous power during maintenance or faults.

For example, a power plant supplying critical industrial loads benefits from this setup. It allows scheduled maintenance without halting power, reducing downtime and operational risks.

Double Bus Double Breaker Arrangement

Understanding the Double Bus Double Breaker Setup

The double bus double breaker arrangement uses two bus bars and two circuit breakers for each circuit. This means every circuit connects to both buses through its own pair of breakers. The key point is that either bus can carry the load at any time without interruption.

This setup doesn't need any special equipment like bus couplers or switches to transfer loads between buses. The circuit breakers themselves handle switching, allowing seamless transfer. Operators can easily switch a circuit from one bus to the other by opening or closing the appropriate breakers.

Because both buses are energized and fully operational, the system provides high reliability. If one bus or breaker needs maintenance or fails, the other bus and breaker can continue supplying power to the circuit without interruption.

This arrangement is common in large power stations or substations where power continuity is critical. It's especially useful in places like hospitals, data centers, or industrial plants where even a brief power loss can cause serious issues.

Key Advantages and Limitations

Advantages:

● High Reliability: Both buses are live, so faults or maintenance on one bus don't interrupt the supply.

● Maximum Flexibility: Circuits can be switched between buses anytime without stopping power.

● Fault Isolation: Faults on one breaker or bus affect only that circuit, minimizing impact.

● Maintenance Friendly: Breakers or buses can be serviced without shutting down the system.

● No Bus Coupler Needed: Simplifies switching since each circuit has its own breakers.

Limitations:

● High Cost: Requires twice the number of circuit breakers, increasing initial investment.

● More Space Needed: Double the breakers and buses require larger switchyard space.

● Higher Maintenance: More equipment means increased upkeep and testing.

● Complex Operation: Operators must carefully coordinate breaker operations to avoid faults.

Applications in Critical Power Systems

This arrangement suits environments where power interruptions are unacceptable. Examples include:

● Hospitals: Life-support and critical medical equipment require continuous power.

● Data Centers: Servers and network equipment need steady, uninterrupted electricity.

● Large Industrial Plants: Production lines rely on constant power to avoid costly downtime.

● Nuclear Power Plants: Safety protocols demand highly reliable power distribution.

● Major Generation Facilities: Ensures stable power output and flexibility in operation.

For instance, a 400 kV switchyard often uses this setup to guarantee supply reliability. It allows scheduled maintenance on one bus while the other carries the full load. This flexibility helps avoid costly outages and enhances overall system security.

One-and-a-Half Breaker Arrangement

Concept and Design

The one-and-a-half breaker arrangement is a clever design used mainly in large power stations. It uses three circuit breakers to serve two circuits. This means each circuit connects to one and a half breakers on average, hence the name. The setup consists of a row of breakers and bus-bars arranged so that two circuits share a middle breaker between them.

This design improves reliability because if a bus fault or breaker failure happens, power can still flow through the other breakers. The arrangement allows continuous supply even during maintenance or faults. The bus-bars are divided into sections, and each circuit is connected between two breakers. This way, one breaker can serve two circuits, reducing the total number of breakers needed compared to the double bus double breaker arrangement.

Advantages and Challenges

Advantages:

● High Reliability: A fault in one breaker or bus does not interrupt the entire system. Power can be rerouted through other breakers.

● Cost Savings: Uses fewer breakers than the double bus double breaker setup, lowering initial costs.

● Flexibility: Circuits can be added or maintained without shutting down the whole system.

● Relay Operation: Bus potential can be used for relay protection, enhancing safety.

Challenges:

● Complex Relaying: Protection schemes are more complicated because faults may require opening two breakers.

● Maintenance Issues: During breaker maintenance, two breakers may need opening, which might leave one circuit running on a single bus and breaker, risking supply interruption if a fault occurs.

● Higher Maintenance Costs: More complex equipment and relaying mean more upkeep.

● Operational Complexity: Operators must carefully coordinate breaker operations to avoid faults and outages.

Suitability for Large Stations

This arrangement suits large power stations handling high power per circuit. It balances reliability and cost by reducing the number of breakers while maintaining supply continuity. It is often used in 400 kV and 750 kV substations where power reliability is critical but budget constraints exist.

For example, a large regional power station serving an extensive grid may use this setup to ensure fault tolerance without the high costs of a double bus double breaker system. It offers a practical compromise between reliability and investment.

Ring Main Arrangement

Design and Operational Flexibility

The ring main arrangement forms a loop by connecting the ends of the bus-bars back to themselves, creating a ring-like shape. This design means each feeder gets power from two different paths. If one section fails or needs maintenance, the other path keeps the power flowing without interruption. This setup localizes faults, so problems affect only the faulty section, while the rest of the system continues working smoothly.

Operators can isolate any part of the ring for repairs without shutting down the entire system. The ring main arrangement uses almost the same number of circuit breakers as a single bus-bar system, so it keeps costs relatively low while boosting reliability and flexibility.

Advantages Over Other Arrangements

● Improved Reliability: Two power paths per feeder mean no single point of failure.

● Fault Localization: Faults affect only one section, minimizing outages.

● Maintenance Without Downtime: Sections can be isolated for service while others stay live.

● Cost-Effective: Uses nearly the same number of breakers as simpler systems.

● Operational Flexibility: Easy switching and load management due to ring structure.

Common Applications

Ring main arrangements are popular in medium and high-voltage substations, especially where reliability matters but budgets are limited. Utilities often use this design in urban distribution networks, ensuring power stays on during repairs or faults.

For example, a city substation serving residential and commercial areas might use a ring main to maintain continuous power. If one feeder or breaker fails, the ring allows supply to reroute quickly, avoiding blackouts.

However, this arrangement can be tricky when adding new circuits, as the ring’s closed loop limits expansion options. Also, opening a breaker section might overload other feeders temporarily, so careful load management is essential.

Mesh Arrangement

Structure of the Mesh Arrangement

The mesh arrangement is a busbar setup where circuit breakers are placed in a mesh-like network formed by interconnected busbars. Instead of having separate busbars for each circuit, the breakers connect at nodes within this mesh. Circuits tap off from these nodes, sharing the busbars. This design allows multiple paths for power flow, increasing system security.

For example, in a mesh arrangement controlling eight circuits, only four circuit breakers may be needed. This contrasts with other setups that require more breakers per circuit. The mesh is formed by busbars arranged in a grid or lattice, and the circuit breakers are strategically placed at intersections.

Benefits and Limitations

Benefits:

● Economic Use of Circuit Breakers: Requires fewer breakers than more complex arrangements like the one-and-a-half breaker system, reducing initial investment.

● Security Against Busbar Faults: If a fault occurs on a busbar section, the mesh opens at two breaker points, isolating the fault and protecting the rest of the system.

● Fault Isolation: Faults are confined to the affected section, minimizing disruption to the overall power supply.

● Suitable for Large Substations: Ideal where many circuits must be controlled efficiently without excessive equipment.

Limitations:

● Lack of Switching Flexibility: The mesh arrangement does not offer switching options to transfer loads between busbars easily.

● Complex Fault Clearing: Clearing faults often requires opening two breakers, which can complicate protection schemes.

● Limited Load Transfer Capability: Unlike double bus or transfer bus arrangements, the mesh setup cannot easily reroute power during maintenance or faults.

● Potential for Complex Maintenance: Due to the interconnected nature, maintenance planning requires careful coordination to avoid unintended outages.

Use in Substations

Mesh arrangements are commonly used in substations that handle a large number of circuits and require economical use of circuit breakers. They provide good fault protection and system security without the high cost and complexity of more redundant systems.

For example, a substation with numerous feeders but limited space and budget might choose a mesh arrangement to balance cost and reliability. It offers a practical solution where complete load transfer flexibility is less critical.

In such substations, the mesh busbars and breakers are arranged to optimize space and reduce equipment count while maintaining acceptable reliability and fault isolation. Operators rely on precise protection coordination to manage faults effectively.

Conclusion

The article explores various busbar arrangements, including single bus-bar, sectionalized, main and transfer, double bus double breaker, one-and-a-half breaker, ring main, and mesh arrangements. Each type offers unique benefits and challenges, catering to different power system needs. Choosing the right busbar arrangement depends on factors like reliability, cost, and maintenance flexibility. For optimal power distribution solutions, consider Hongmao's innovative products, which are designed to enhance efficiency and reliability while meeting diverse operational demands.

FAQ

Q: What is a Power Busbar?

A: A Power Busbar is a metallic strip or bar used in power systems to conduct electricity within a switchboard, distribution board, substation, or other electrical apparatus.

Q: How does a Power Busbar improve system reliability?

A: A Power Busbar enhances reliability by providing multiple pathways for power flow, allowing for fault isolation and maintenance without disrupting the entire system.

Q: Why is the single bus-bar arrangement cost-effective?

A: The single bus-bar arrangement is cost-effective because it uses fewer components, resulting in lower initial costs and simplified maintenance.